How to Build a Wind Powered Water Pump

Wind-powered water pump usher in a new era of sustainability, providing a lifeline to those living in distant or off-grid areas who desperately need access to water.

In a world facing environmental concerns, these inventive systems serve as beacons of hope, harnessing nature’s power to meet our fundamental needs. Consider a solution transcending conventional constraints, where a whisper in the wind becomes a lifeline.

Wind-powered water pumps promise a stable respite in desert regions and remote settlements. Join us as we explore the world of possibility, where innovation meets necessity.

Table of Contents

What Are the Components of a Wind-Powered Water Pump?

To build a wind-powered water pump, you must first comprehend the system’s main components.

The main components are the rotor assembly, the gearbox and transmission system, and the pump mechanism.

Each component is critical to capturing wind energy and transforming it into usable water pump power.

Rotor Assembly

The rotor assembly, which consists of blades attached to a central hub, collects the wind’s kinetic energy. This energy is then directed to the rotor shaft, which begins the transformation process.

With each gust, the blades dance in perfect rhythm, seizing nature’s invisible power. This exquisite device harnesses the wind’s breath, propelling the system toward its goal: drawing water from the earth’s depths and delivering it to needy people.

Gearbox and Transmission System

The gearbox and transmission system increases the rotor shaft’s rotational speed, allowing it to drive the water pump mechanism more efficiently. This critical stage guarantees that energy is transferred smoothly from the rotor to the pump, maximizing efficiency in wind power generation.

Through precise engineering, each component works together to move the system towards its goal: supplying water sustainably using wind power.

Pump Mechanism

The pump mechanism converts the gearbox’s rotational motion into vertical or horizontal movement, depending on the pump type.

Its primary duty is to extract and transfer water from the source to its intended destination, completing the wind-powered cycle of sustainable water distribution.

Also read >>> The Best Hybrid Solar Inverters for You

Selecting the Best Materials for Your Project

Choosing the correct materials is critical for maintaining the wind-powered water pump’s longevity and efficiency. It lays the groundwork for long-term dependability and peak performance.

Durability and Efficiency of Gearbox Components

Gearbox components must withstand extreme conditions like high-speed rotations and torque loads.

To satisfy these requirements, stainless steel or hardened alloys are used due to their strength and resistance to wear. This increases the gearbox’s durability and reliability in converting wind energy into mechanical power.

Corrosion-resistant Pump Materials

Pump materials must be corrosion-resistant due to their exposure to water.

Stainless steel and PVC are excellent choices because of their durability and low maintenance requirements.

This ensures the pump’s lifespan and operation in water-intensive situations.

Designing the System

Designing the system involves calculating the dimensions and specifications for optimal performance.

Calculating Optimal Blade Length and Number

The length and number of rotor blades determine how efficiently energy is captured.

Wind speed and site location are critical components in establishing the best arrangement.

By carefully examining these characteristics, the system may be fine-tuned to maximum energy extraction, ensuring that every gust contributes to the long-term production of water power.

Gear Ratio Determination for Maximum Output

The gear ratio between the rotor shaft and the pump mechanism determines rotational speed and torque.

Calculating this ratio is crucial to achieving the optimum pumping capacity.

The system optimizes energy transmission by carefully selecting the optimum gearing, assuring efficient operation and steady water delivery. This precision engineering ensures that wind power is efficiently harvested for long-term water access.

Sizing the Pump for the Desired Flow Rate

The required flow rate and head pressure determine the pump size.

Aligning the pump’s dimensions with the application ensures optimum water delivery. This rigorous sizing approach maximizes performance, ensuring that the system meets the exact water access requirements while maximizing energy efficiency.

Also read >>> The Best Water Pressure Booster Pump

Construction Process

Assembling the components follows a systematic approach to ensure proper functionality and safety.

Assembling the Rotor Assembly

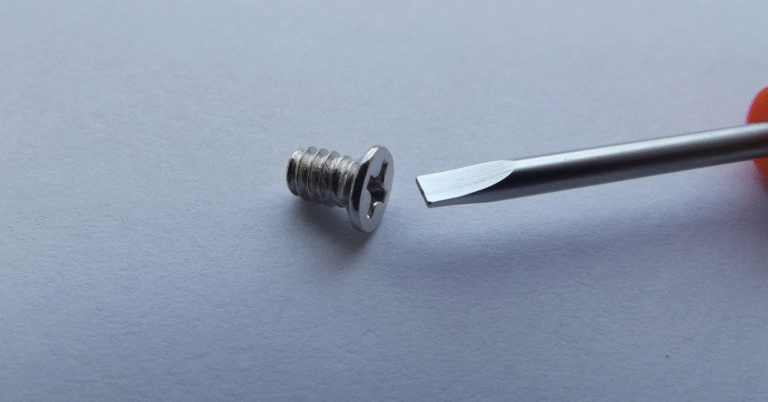

The rotor assembly is made up of blades that are secured to the hub using bolts or adhesive.

Achieving balance in blade location is critical to maintaining smooth performance.

This rigorous technique improves performance and reduces vibrations or uneven strains, maximizing the system’s dependability and endurance while using wind power for water-pumping applications.

Integrating Gearbox and Transmission

Connecting the gearbox to the rotor shaft and integrating it into the transmission system necessitates precise positioning and alignment.

Lubricating the components reduces friction and wear, assuring smooth operation and extending the system’s life. It also efficiently transfers wind energy into mechanical power for water pumping.

Installing and Connecting the Water Pump

The final step in the construction process is to install the water pump and connect it to the transmission system.

The system’s design requirements make wiring or pipe connections. This final stage ensures that all components are seamlessly integrated.

This results in a fully operational wind-powered water pump ready to harness nature’s energy and give sustainable access to water in remote or off-grid places.

Maintenance and Troubleshooting

Regular maintenance is essential to ensure the continued operation and performance of the wind-powered water pump.

Regular Inspection and Lubrication

Regularly inspecting components for signs of wear and tear and applying lubricant to moving parts considerably increases the system’s lifespan.

Prompt attention to any signs of damage or malfunction is critical.

The wind-powered water pump remains operational and reliable by remaining vigilant and correcting difficulties as they arise, enabling uninterrupted access to water in even the most adverse circumstances.

Monitoring Performance Metrics

Monitoring performance measures, such as pump efficiency and water output, allows for early diagnosis of potential faults.

Adjustments can then be made to improve performance as needed.

A proactive strategy guarantees that the wind-powered water pump runs at its full performance, providing dependable water access while reducing energy consumption and environmental effects.

Common Issues and Solutions

Over time, frequent problems such as bearing failure or pump clogs may arise.

Implementing troubleshooting processes is critical to quickly resolving such issues and reducing downtime.

By establishing processes to handle these difficulties as soon as possible, the wind-powered water pump can continue continuous operation, ensuring reliable water access while minimizing disruptions to operations in distant or off-grid places.

Also read >>> The Best Float Switch for Water Tank

Conclusion

A wind-powered water pump requires careful planning, precise construction, and ongoing maintenance.

Nonetheless, these efforts result in an autonomous solution for water access in rural or off-grid locations.

Understanding the components, selecting appropriate materials, and adhering to construction and maintenance regulations can help individuals or groups ensure reliable water sources while reducing environmental effects.

This comprehensive approach ensures water availability and promotes sustainability, allowing communities to thrive under challenging conditions.

Also read >>> The Best Solar Water Heaters for You